Advertisement

A Kid-friendly Introduction to Magnets and Magnetism

- Share Content on Facebook

- Share Content on LinkedIn

- Share Content on Flipboard

- Share Content on Reddit

- Share Content via Email

This explainer on magnets and magnetism is intended for our elementary and middle-school readers. If you're feeling magnetically drawn to read more on this topic, check out our long-form article How Magnets Work .

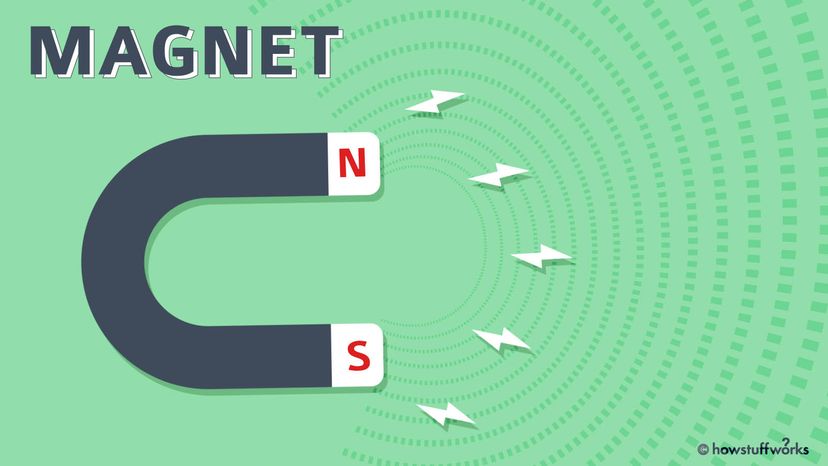

Magnets are fun to play with. It feels like you have a magic wand! Magnets are pieces of metal or rock with an invisible power to attract special kinds of metal. That power is called a force. In nature, a force is something that causes a push or a pull. Gravity is the force that keeps you from floating off the ground. Magnetism is the force that makes a magnet stick to your refrigerator.

The Earth Is a Magnet

Magnetism is at work all around you. Almost everything that uses electricity or runs with a motor has magnets in it. The magnetic force helps your car run, your microwave cook and your computer work. Even the Earth we live on is a giant magnet!

The middle of our planet is made of two metals called iron and nickel. Both metals are attracted to magnets. These special metals can also become magnets. Our planet is always turning around in space, and Earth's metal core is turning, too. These movements make a magnetic force that surrounds the Earth called a magnetic field.

A magnetic field is the area around a magnet that has magnetic force. All magnets have a magnetic field, no matter how big they are. Things that are attracted to magnets are called magnetic objects. All magnetic objects are made of metal, but not all metals are magnetic. The main metals that are attracted by magnets are iron, cobalt and nickel. You can turn one of these metals into a magnet by rubbing it with a magnet!

If a magnetic object like a paper clip enters a magnetic field, it is pulled toward the magnet. Magnetic fields even work under water. A strong magnet can even attract a magnetic object through a table.

Magnets Have Two Poles: North and South

A magnet has two ends, called poles. One end is the north pole, and the other is the south pole. Can you think of something else that has a north pole and a south pole? That's right — Earth is a lot like a magnet! Compasses work by magnetizing the rotating hand so it lines up with the magnetic poles of the planet.

If you hold two magnets in your hands, the north pole of one magnet will always attract the south pole of another. Opposite poles push each other away.

Because our planet is like a big magnet, it also has a magnetic field. Earth's magnetic field protects us from the sun's radiation. The North and South poles have natural colorful light shows called northern and southern lights. These lights are caused by sprays of energy coming off the sun bumping into the magnetic field of Earth.

The needle of a compass is a magnet, and it spins to line up with the poles of Earth, north and south.

Frequently Answered Questions

What is magnetism in magnets, what is the difference between magnet and magnetism.

Please copy/paste the following text to properly cite this HowStuffWorks.com article:

How does a magnetic paper work?

Explore the science behind magnetic paper, its composition, versatile applications, and how it revolutionizes education, organization, and decor.

Unraveling the Mystery of Magnetic Paper

Magnetic paper is a fascinating innovation that combines the properties of magnets with the flexibility and usability of paper. It has a myriad of applications, ranging from educational tools to creative projects and functional items. In this article, we will delve into the inner workings of magnetic paper and explore its various uses.

Understanding the Composition of Magnetic Paper

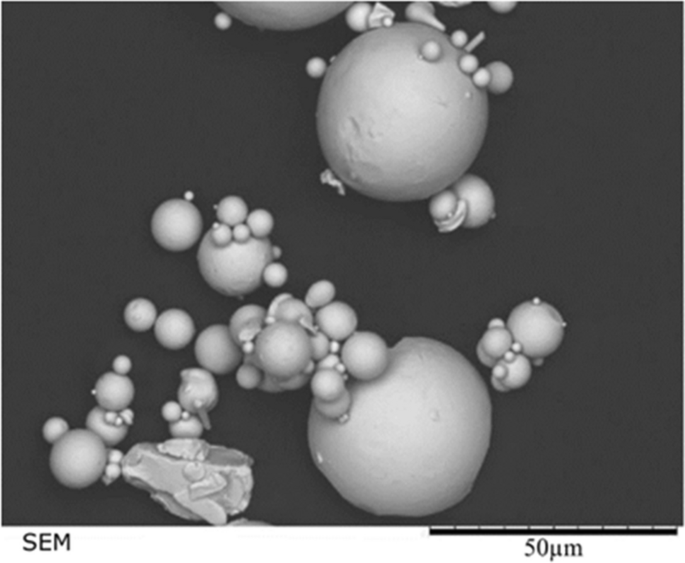

Magnetic paper is created by embedding small magnetic particles within a flexible, paper-like material. Typically, these particles consist of either iron or a ferrite-based compound. These particles are dispersed uniformly throughout the material, ensuring consistent magnetic properties across the entire surface.

The magnetic particles are then coated with a protective layer, usually made of plastic or a similar material, to prevent them from damaging the surrounding paper. This coating also makes the magnetic paper more durable and resistant to wear and tear.

Creating Custom Magnetic Surfaces

One of the primary advantages of magnetic paper is its ability to be easily cut and shaped into various forms, making it a versatile material for many applications. The most common method for cutting magnetic paper is using scissors or a cutting machine, which can create intricate shapes and patterns with ease.

Additionally, magnetic paper can be printed on using an inkjet or laser printer, allowing for the creation of custom designs and graphics. This feature makes magnetic paper an excellent choice for creating personalized items, such as fridge magnets, promotional materials, and educational tools.

Exploring the Many Uses of Magnetic Paper

- Educational Tools: Magnetic paper can be used to create interactive learning aids, such as magnetic maps, alphabet letters, and puzzle pieces. These tools can help students better understand and engage with various subjects, from geography to language arts.

- Organizational Aids: Magnetic paper is an ideal material for creating labels and signs that can be easily moved and rearranged on magnetic surfaces. This flexibility makes it perfect for use in offices, warehouses, and classrooms to keep track of inventory, schedules, and more.

- Decorative Items: With the ability to print custom designs and images on magnetic paper, it becomes an excellent medium for creating personalized and unique decorative items. These can include photo magnets, wall art, and other creative projects.

- Promotional Materials: Businesses and organizations can use magnetic paper to create custom promotional items, such as business cards, fridge magnets, and calendar magnets, which can be easily distributed and displayed on magnetic surfaces.

In conclusion, magnetic paper is a versatile and innovative material that combines the properties of magnets with the usability of paper. Its diverse applications and ease of customization make it an invaluable tool for educational, organizational, and creative purposes. As technology continues to advance, we can expect even more innovative uses for magnetic paper in the future.

Related Posts:

The primary purpose of this project is to help the public to learn some exciting and important information about electricity and magnetism.

Privacy Policy

Our Website follows all legal requirements to protect your privacy. Visit our Privacy Policy page.

The Cookies Statement is part of our Privacy Policy.

Editorial note

The information contained on this website is for general information purposes only. This website does not use any proprietary data. Visit our Editorial note.

Copyright Notice

It’s simple:

1) You may use almost everything for non-commercial and educational use.

2) You may not distribute or commercially exploit the content, especially on another website.

The Science of How Magnets Work

- Chemical Laws

- Periodic Table

- Projects & Experiments

- Scientific Method

- Biochemistry

- Physical Chemistry

- Medical Chemistry

- Chemistry In Everyday Life

- Famous Chemists

- Activities for Kids

- Abbreviations & Acronyms

- Weather & Climate

- Ph.D., Biomedical Sciences, University of Tennessee at Knoxville

- B.A., Physics and Mathematics, Hastings College

The force produced by a magnet is invisible and mystifying. Have you ever wondered how magnets work ?

Key Takeaways: How Magnets Work

- Magnetism is a physical phenomenon by which a substance is attracted or repelled by a magnetic field.

- The two sources of magnetism are electric current and spin magnetic moments of elementary particles (primarily electrons).

- A strong magnetic field is produced when the electron magnetic moments of a material are aligned. When they are disordered, the material is neither strongly attracted nor repelled by a magnetic field.

What Is a Magnet?

A magnet is any material capable of producing a magnetic field . Since any moving electric charge generates a magnetic field, electrons are tiny magnets. This electric current is one source of magnetism. However, the electrons in most materials are randomly oriented, so there is little or no net magnetic field. To put it simply, the electrons in a magnet tend to be oriented the same way. This happens naturally in many ions, atoms, and materials when they are cooled, but isn't as common at room temperature. Some elements (e.g., iron, cobalt, and nickel) are ferromagnetic (can be induced to become magnetized in a magnetic field) at room temperature. For these elements , the electrical potential is lowest when the magnetic moments of the valence electrons are aligned. Many other elements are diamagnetic . The unpaired atoms in diamagnetic materials generate a field that weakly repels a magnet. Some materials don't react with magnets at all.

The Magnetic Dipole and Magnetism

The atomic magnetic dipole is the source of magnetism. On the atomic level, magnetic dipoles mainly are the result of two types of movement of the electrons. There is the orbital motion of the electron around the nucleus, which produces an orbital dipole magnetic moment. The other component of the electron magnetic moment is due to the spin dipole magnetic moment. However, the movement of electrons around the nucleus isn't really an orbit, nor is the spin dipole magnetic moment associated with actual 'spinning' of the electrons. Unpaired electrons tend to contribute to a material's ability to become magnetic since the electron magnetic moment can't be totally canceled out when there are 'odd' electrons.

The Atomic Nucleus and Magnetism

The protons and neutrons in the nucleus also have orbital and spin angular momentum, and magnetic moments. The nuclear magnetic moment is much weaker than the electronic magnetic moment because although the angular momentum of the different particles may be comparable, the magnetic moment is inversely proportional to mass (mass of an electron is much less than that of a proton or neutron). The weaker nuclear magnetic moment is responsible for nuclear magnetic resonance (NMR), which is used for magnetic resonance imaging (MRI).

- Cheng, David K. (1992). Field and Wave Electromagnetics . Addison-Wesley Publishing Company, Inc. ISBN 978-0-201-12819-2.

- Du Trémolet de Lacheisserie, Étienne; Damien Gignoux; Michel Schlenker (2005). Magnetism: Fundamentals . Springer. ISBN 978-0-387-22967-6.

- Kronmüller, Helmut. (2007). Handbook of Magnetism and Advanced Magnetic Materials . John Wiley & Sons. ISBN 978-0-470-02217-7.

- What Is Magnetism? Definition, Examples, Facts

- Electron Definition: Chemistry Glossary

- Paramagnetism Definition and Examples

- Dipole Definition in Chemistry and Physics

- How to Tell If an Element Is Paramagnetic or Diamagnetic

- The Relationship Between Electricity and Magnetism

- Quantum Numbers and Electron Orbitals

- Learn What Metals Are Magnetic and Why

- Basic Model of the Atom and Atomic Theory

- Atoms and Atomic Theory - Study Guide

- Not All Iron Is Magnetic (Magnetic Elements)

- The Basics: An Introduction to Electricity and Electronics

- How to Demagnetize a Magnet

- FAQ: What is Electricity?

- Make an Atom Model

- Atom Definition and Examples

- school Campus Bookshelves

- menu_book Bookshelves

- perm_media Learning Objects

- login Login

- how_to_reg Request Instructor Account

- hub Instructor Commons

- Download Page (PDF)

- Download Full Book (PDF)

- Periodic Table

- Physics Constants

- Scientific Calculator

- Reference & Cite

- Tools expand_more

- Readability

selected template will load here

This action is not available.

22.1: Magnets

- Last updated

- Save as PDF

- Page ID 2695

Learning Objectives

By the end of this section, you will be able to:

- Describe the difference between the north and south poles of a magnet.

- Describe how magnetic poles interact with each other.

All magnets attract iron, such as that in a refrigerator door. However, magnets may attract or repel other magnets. Experimentation shows that all magnets have two poles. If freely suspended, one pole will point toward the north. The two poles are thus named the north magnetic pole and the south magnetic pole (or more properly, north-seeking and south-seeking poles, for the attractions in those directions).

UNIVERSAL CHARACTERISTICS OF MAGNETS AND MAGNET POLES

It is a universal characteristic of all magnets that like poles repel and unlike poles attract . (Note the similarity with electrostatics: unlike charges attract and like charges repel.)

Further experimentation shows that it is impossible to separate north and south poles in the manner that + and − charges can be separated.

MISCONCEPTION ALERT: EARTH'S GEOGRAPHIC NORTH POLE HIDES AN S

The Earth acts like a very large bar magnet with its south-seeking pole near the geographic North Pole. That is why the north pole of your compass is attracted toward the geographic north pole of the Earth—because the magnetic pole that is near the geographic North Pole is actually a south magnetic pole! Confusion arises because the geographic term “North Pole” has come to be used (incorrectly) for the magnetic pole that is near the North Pole. Thus, “North magnetic pole” is actually a misnomer—it should be called the South magnetic pole.

The fact that magnetic poles always occur in pairs of north and south is true from the very large scale—for example, sunspots always occur in pairs that are north and south magnetic poles—all the way down to the very small scale. Magnetic atoms have both a north pole and a south pole, as do many types of subatomic particles, such as electrons, protons, and neutrons.

MAKING CONNECTIONS: TAKE-HOME EXPERIMENT -- REFRIGERATOR MAGNETS

We know that like magnetic poles repel and unlike poles attract. See if you can show this for two refrigerator magnets. Will the magnets stick if you turn them over? Why do they stick to the door anyway? What can you say about the magnetic properties of the door next to the magnet? Do refrigerator magnets stick to metal or plastic spoons? Do they stick to all types of metal?

- Magnetism is a subject that includes the properties of magnets, the effect of the magnetic force on moving charges and currents, and the creation of magnetic fields by currents.

- There are two types of magnetic poles, called the north magnetic pole and south magnetic pole.

- North magnetic poles are those that are attracted toward the Earth’s geographic north pole.

- Like poles repel and unlike poles attract.

- Magnetic poles always occur in pairs of north and south—it is not possible to isolate north and south poles.

Physics Bootcamp

Samuel J. Ling

Section 38.2 Permanent and Temporary Magnets

Magnetism in magnets can be temporary or permanent. You are already familiar with permanent magnets, such as the refrigerator magnets. Permanent magnets are magnetized materials that have magnetism already built into them and whose magnetism is not easily destroyed.

Magnetic materials near a magnet also act as it they were magnets. For instance, a paper clip hanging from a magnet attracts other paper clips as illustrated on the right. The first paper clip is an example of a temporary magnet.

Similarly, electromagnets have magnetic property when current is flowing in the coil surrounding them. These are examples of Temporary magnets since their magnetism is not permanent.

Magnetizable materials, such as iron, cobalt, and nickel, can be transformed into permanent magnets by stroking the material with a permanent magnet as illustrated in Figure 38.2.2 .

First, place an unmagnetized iron bar on a table. Now, take a permanent magnet and rub the iron bar with the same pole of the magnet along the length of the iron bar in the same direction over and over again as indicated. The iron bar will become permanently magnetized!

Why do magnetizable materials become magnetized while other materials do not? You can trace the origin of magnetism in materials to the atomic level. Many atoms are tiny magnets themselves. In many materials, called ferromagnets or ferrimagnets , atomic magnets interact with each other such that they tend to align each other's poles.

In ferromagnets, the interatomic forces tend to align their magnetic poles, but thermal vibration tends to randomize them. If temperature is low enough, we find domains where atomic magnets are aligned overwhelmingly in one direction as shown in Figure 38.2.3 . When the domains are small and randomly oriented, the piece of material does not act as a permanent magnet, but when the domains are large and overall oriented in similar directions, the piece would be a permanent magnet.

When a material with atomic magnets is placed near a magnet, say near the South Pole of a permanent magnet, then the force of the external magnet tends to preferentially align the atomic magnets so that North Pole of the atomic magnet faces the South Pole of the external magnet. This leads to growth of magnetic domains that are aligned with the external magnet and large magnetic domains form that are oriented more or less in the direction of the external Poles.

Subsection 38.2.1 Electromagnets

In April of 1820 Hans Christian Øersted of University of Copenhagen (Denmark) published a remarkable discovery that united the subjects of electricity and magnetism. It is said that, while performing physics demonstrations for students, Øersted noticed that, whenever he turned on the current in the wire, a magnetic needle placed nearby also reacted to the current as illustrated in Figure 38.2.4 .

An electromagnet makes use of the magnetism of moving charges in current carrying wires. We will study this fundamental aspect of magnetism in the succeeding chapter. To enhance the impact of current, the wire carrying a current is wound in loops with current flowing in the same direction in each loop. The magnetic field of each loop of current add together to enhance their magnetic effect.

The magnetism of electromagnets can be demonstrated by bringing a permanent magnet near an electromagnet as shown in Figure 38.2.5 . The electromagnet acts just like a bar magnet with two poles since it attracts the North pole of the suspended permanent magnet when the current is one direction and repels the magnet when the orientation of the current is reversed. Electromagnet is an example of a temporary magnet that acts as a magnet when current through the material is on and as a non-magnet when the current is off.

Often, current carrying wires are wound around magnetizable material so that magnetic field of the current and the magnetized material add to produce a more powerful electromagnet. This is another way to transform a magnetizable material such as an iron bar into a permanent magnet. This is a preferred method of making new permanent magnets than by stroking the material.

Magnetic Fields

After reading this section you will be able to do the following:.

- Explain how magnetic lines of flux are affected by other magnetic fields.

In each of the following pictures a magnet is put onto a piece of paper. Then a light dusting of iron filings is sprinkled around the magnet. The lines around the magnets in the following pictures are produced by the iron filings gathering together around the field lines.

What does the pattern made by the iron particles indicate?

You learned in a previous experiment that no matter how many pieces you cut a magnet into, each piece is still a magnet. Even if you shred a magnet into particles the size of sand, each tiny grain is a magnet with a north pole and a south pole. When these magnetized particles are sprinkled over the magnet in Box A, the resulting pattern shows the magnetic field around a single magnet. We can see that the force of the magnet is the strongest at the two ends because more iron particles are concentrated in these areas. The magnetic lines of flux flow from one end to the other.

How do you explain what is occurring?

To understand what is happening, recall from a previous experiment that a magnet allowed to stand freely, like a compass needle, will point to the north in response to the earth’s magnetic field unless it is near a strong magnetic. If the compass is near a strong bar magnet, the opposite poles of the magnets are attracted to each other. We can use this knowledge to identify the magnetic field of a magnet by placing a compass at various locations around the bar magnet and observing where the compass needle points. If the compass is far away from the bar magnet the compass will always point north because it is not in the bar magnet’s magnetic field. As it gets closer to the magnet, the compass begins to point more and more toward the magnet as a result of the force, or the magnetic field, of the magnet. The compass needle aligns itself with the magnetic flux lines of the magnet.

Let's say that instead of using one compass to move around the bar magnet, we place thousands of tiny compass needles all around the bar magnet and watch which direction they point and what pattern they make. That is what is happening in our experiment with the iron filings. Each tiny magnetic iron filing is a tiny magnet with a north and south pole, just like a tiny compass. When the iron filings are sprinkled, those very close to the magnet, where the magnetic force is the strongest, will cling to the magnet.

Those filings a little farther away, where the magnetic force is less strong, will align themselves with the magnetic flux lines, but they will not be drawn to cling to the magnet. Those filings even farther away, outside the magnetic force, will point north in response to the earth’s magnetic field. These patterns formed by the direction of the tiny compasses can tell us something about where the magnetic force is the strongest, where it is an attracting force, and where it is a repelling force. In Box B, this pattern indicates a repelling force because the tiny magnets are moving away from the ends of the larger bar magnets. Looking at the pattern in Box C, you see that the two ends of these magnets are attracted because the tiny magnets appear to be lined end to end, attracting to one another and also attracting to the ends of the larger bar magnets.

- The force of the magnet is the strongest at the two ends.

20.1 Magnetic Fields, Field Lines, and Force

Section learning objectives.

By the end of this section, you will be able to do the following:

- Summarize properties of magnets and describe how some nonmagnetic materials can become magnetized

- Describe and interpret drawings of magnetic fields around permanent magnets and current-carrying wires

- Calculate the magnitude and direction of magnetic force in a magnetic field and the force on a current-carrying wire in a magnetic field

Teacher Support

The learning objectives in this section will help your students master the following standards:

- (G) investigate and describe the relationship between electric and magnetic fields in applications such as generators, motors, and transformers.

In addition, the High School Physics Laboratory Manual addresses content in this section in the lab titled: Magnetism, as well as the following standards:

Section Key Terms

Magnets and magnetization.

People have been aware of magnets and magnetism for thousands of years. The earliest records date back to ancient times, particularly in the region of Asia Minor called Magnesia—the name of this region is the source of words like magnet . Magnetic rocks found in Magnesia, which is now part of western Turkey, stimulated interest during ancient times. When humans first discovered magnetic rocks, they likely found that certain parts of these rocks attracted bits of iron or other magnetic rocks more strongly than other parts. These areas are called the poles of a magnet. A magnetic pole is the part of a magnet that exerts the strongest force on other magnets or magnetic material, such as iron. For example, the poles of the bar magnet shown in Figure 20.2 are where the paper clips are concentrated.

If a bar magnet is suspended so that it rotates freely, one pole of the magnet will always turn toward the north, with the opposite pole facing south. This discovery led to the compass, which is simply a small, elongated magnet mounted so that it can rotate freely. An example of a compass is shown Figure 20.3 . The pole of the magnet that orients northward is called the north pole , and the opposite pole of the magnet is called the south pole .

The discovery that one particular pole of a magnet orients northward, whereas the other pole orients southward allowed people to identify the north and south poles of any magnet. It was then noticed that the north poles of two different magnets repel each other, and likewise for the south poles. Conversely, the north pole of one magnet attracts the south pole of other magnets. This situation is analogous to that of electric charge, where like charges repel and unlike charges attract. In magnets, we simply replace charge with pole : Like poles repel and unlike poles attract. This is summarized in Figure 20.4 , which shows how the force between magnets depends on their relative orientation.

Consider again the fact that the pole of a magnet that orients northward is called the north pole of the magnet. If unlike poles attract, then the magnetic pole of Earth that is close to the geographic North Pole must be a magnetic south pole! Likewise, the magnetic pole of Earth that is close to the geographic South Pole must be a magnetic north pole. This situation is depicted in Figure 20.5 , in which Earth is represented as containing a giant internal bar magnet with its magnetic south pole at the geographic North Pole and vice versa. If we were to somehow suspend a giant bar magnet in space near Earth, then the north pole of the space magnet would be attracted to the south pole of Earth’s internal magnet. This is in essence what happens with a compass needle: Its magnetic north pole is attracted to the magnet south pole of Earth’s internal magnet.

What happens if you cut a bar magnet in half? Do you obtain one magnet with two south poles and one magnet with two north poles? The answer is no: Each half of the bar magnet has a north pole and a south pole. You can even continue cutting each piece of the bar magnet in half, and you will always obtain a new, smaller magnet with two opposite poles. As shown in Figure 20.6 , you can continue this process down to the atomic scale, and you will find that even the smallest particles that behave as magnets have two opposite poles. In fact, no experiment has ever found any object with a single magnetic pole, from the smallest subatomic particle such as electrons to the largest objects in the universe such as stars. Because magnets always have two poles, they are referred to as magnetic dipoles — di means two . Below, we will see that magnetic dipoles have properties that are analogous to electric dipoles.

Watch Physics

Introduction to magnetism.

This video provides an interesting introduction to magnetism and discusses, in particular, how electrons around their atoms contribute to the magnetic effects that we observe.

Grasp Check

Toward which magnetic pole of Earth is the north pole of a compass needle attracted?

- The north pole of a compass needle is attracted to the north magnetic pole of Earth, which is located near the geographic North Pole of Earth.

- The north pole of a compass needle is attracted to the south magnetic pole of Earth, which is located near the geographic North Pole of Earth.

- The north pole of a compass needle is attracted to the north magnetic pole of Earth, which is located near the geographic South Pole of Earth.

- The north pole of a compass needle is attracted to the south magnetic pole of Earth, which is located near the geographic South Pole of Earth.

Only certain materials, such as iron, cobalt, nickel, and gadolinium, exhibit strong magnetic effects. Such materials are called ferromagnetic , after the Latin word ferrum for iron. Other materials exhibit weak magnetic effects, which are detectable only with sensitive instruments. Not only do ferromagnetic materials respond strongly to magnets—the way iron is attracted to magnets—but they can also be magnetized themselves—that is, they can be induced to be magnetic or made into permanent magnets ( Figure 20.7 ). A permanent magnet is simply a material that retains its magnetic behavior for a long time, even when exposed to demagnetizing influences.

When a magnet is brought near a previously unmagnetized ferromagnetic material, it causes local magnetization of the material with unlike poles closest, as in the right side of Figure 20.7 . This causes an attractive force, which is why unmagnetized iron is attracted to a magnet.

What happens on a microscopic scale is illustrated in Figure 7(a) . Regions within the material called domains act like small bar magnets. Within domains, the magnetic poles of individual atoms are aligned. Each atom acts like a tiny bar magnet. Domains are small and randomly oriented in an unmagnetized ferromagnetic object. In response to an external magnetic field, the domains may grow to millimeter size, aligning themselves, as shown in Figure 7(b) . This induced magnetization can be made permanent if the material is heated and then cooled, or simply tapped in the presence of other magnets.

Conversely, a permanent magnet can be demagnetized by hard blows or by heating it in the absence of another magnet. Increased thermal motion at higher temperature can disrupt and randomize the orientation and size of the domains. There is a well-defined temperature for ferromagnetic materials, which is called the Curie temperature , above which they cannot be magnetized. The Curie temperature for iron is 1,043 K (770 °C °C ), which is well above room temperature. There are several elements and alloys that have Curie temperatures much lower than room temperature and are ferromagnetic only below those temperatures.

Refrigerator Magnets

We know that like magnetic poles repel and unlike poles attract. See if you can show this for two refrigerator magnets. Will the magnets stick if you turn them over? Why do they stick to the refrigerator door anyway? What can you say about the magnetic properties of the refrigerator door near the magnet? Do refrigerator magnets stick to metal or plastic spoons? Do they stick to all types of metal?

Holding a magnetic close to an unmagnetized ferromagnetic material will magnetically polarize the ferromagnetic material, causing the atomic magnetic dipoles to orient towards the external magnet. This is similar to electric polarization. Thus, the ferromagnetic material becomes magnetized in the presence of the external magnet, and the two magnets attract each other. For a magnet to stick to the refrigerator door, the door must contain some ferromagnetic material. Magnets will stick to ferrous spoons, for example spoons with iron in them, but not to nonferrous spoons, such as spoons made from Al or Ag, and will not stick to a magnet. Magnets will also not stick to plastic spoons.

You have one magnet with the north and south poles labeled. How can you use this magnet to identify the north and south poles of other magnets?

- If the north pole of a known magnet is repelled by a pole of an unknown magnet on bringing them closer, that pole of unknown magnet is its north pole; otherwise, it is its south pole.

- If the north pole of known magnet is attracted to a pole of an unknown magnet on bringing them closer, that pole of unknown magnet is its north pole; otherwise, it is its south pole.

Magnetic Fields

We have thus seen that forces can be applied between magnets and between magnets and ferromagnetic materials without any contact between the objects. This is reminiscent of electric forces, which also act over distances. Electric forces are described using the concept of the electric field, which is a force field around electric charges that describes the force on any other charge placed in the field. Likewise, a magnet creates a magnetic field around it that describes the force exerted on other magnets placed in the field. As with electric fields, the pictorial representation of magnetic field lines is very useful for visualizing the strength and direction of the magnetic field.

As shown in Figure 20.9 , the direction of magnetic field lines is defined to be the direction in which the north pole of a compass needle points. If you place a compass near the north pole of a magnet, the north pole of the compass needle will be repelled and point away from the magnet. Thus, the magnetic field lines point away from the north pole of a magnet and toward its south pole.

Magnetic field lines can be mapped out using a small compass. The compass is moved from point to point around a magnet, and at each point, a short line is drawn in the direction of the needle, as shown in Figure 20.10 . Joining the lines together then reveals the path of the magnetic field line. Another way to visualize magnetic field lines is to sprinkle iron filings around a magnet. The filings will orient themselves along the magnetic field lines, forming a pattern such as that shown on the right in Figure 20.10 .

Virtual Physics

Using a compass to map out the magnetic field.

This simulation presents you with a bar magnet and a small compass. Begin by dragging the compass around the bar magnet to see in which direction the magnetic field points. Note that the strength of the magnetic field is represented by the brightness of the magnetic field icons in the grid pattern around the magnet. Use the magnetic field meter to check the field strength at several points around the bar magnet. You can also flip the polarity of the magnet, or place Earth on the image to see how the compass orients itself.

With the slider at the top right of the simulation window, set the magnetic field strength to 100 percent . Now use the magnetic field meter to answer the following question: Near the magnet, where is the magnetic field strongest and where is it weakest? Don’t forget to check inside the bar magnet.

- The magnetic field is strongest at the center and weakest between the two poles just outside the bar magnet. The magnetic field lines are densest at the center and least dense between the two poles just outside the bar magnet.

- The magnetic field is strongest at the center and weakest between the two poles just outside the bar magnet. The magnetic field lines are least dense at the center and densest between the two poles just outside the bar magnet.

- The magnetic field is weakest at the center and strongest between the two poles just outside the bar magnet. The magnetic field lines are densest at the center and least dense between the two poles just outside the bar magnet.

- The magnetic field is weakest at the center and strongest between the two poles just outside the bar magnet and the magnetic field lines are least dense at the center and densest between the two poles just outside the bar magnet.

When two magnets are brought close together, the magnetic field lines are perturbed, just as happens for electric field lines when two electric charges are brought together. Bringing two north poles together—or two south poles—will cause a repulsion, and the magnetic field lines will bend away from each other. This is shown in Figure 20.11 , which shows the magnetic field lines created by the two closely separated north poles of a bar magnet. When opposite poles of two magnets are brought together, the magnetic field lines join together and become denser between the poles. This situation is shown in Figure 20.11 .

Like the electric field, the magnetic field is stronger where the lines are denser. Thus, between the two north poles in Figure 20.11 , the magnetic field is very weak because the density of the magnetic field is almost zero. A compass placed at that point would essentially spin freely if we ignore Earth’s magnetic field. Conversely, the magnetic field lines between the north and south poles in Figure 20.11 are very dense, indicating that the magnetic field is very strong in this region. A compass placed here would quickly align with the magnetic field and point toward the south pole on the right.

Misconception Alert

The density of the magnetic field lines in Figure 20.11 indicates the magnitude of the force that would be applied to a small test magnet placed in this field. The density does not indicate the force between the two magnets that create the field. The magnitude of the force between the two magnets is the same in both cases in Figure 20.11 . This can be understood by imagining that you place one of the magnets in the field of the other magnet. This situation is symmetrical: The magnetic fields look the same—other than direction—for both situations shown in Figure 20.11 . Because the magnets are of equal strength, they perturb the magnetic field of the opposite magnet, which is why the magnetic field must be probed by a small magnetic such as, a compass.

Note that magnets are not the only things that make magnetic fields. Early in the nineteenth century, people discovered that electrical currents cause magnetic effects. The first significant observation was by the Danish scientist Hans Christian Oersted (1777–1851), who found that a compass needle was deflected by a current-carrying wire. This was the first significant evidence that the movement of electric charges had any connection with magnets. An electromagnet is a device that uses electric current to make a magnetic field. These temporarily induced magnets are called electromagnets. Electromagnets are employed for everything from a wrecking yard crane that lifts scrapped cars to controlling the beam of a 90-km-circumference particle accelerator to the magnets in medical-imaging machines (see Figure 20.12 ).

The magnetic field created by an electric current in a long straight wire is shown in Figure 20.13 . The magnetic field lines form concentric circles around the wire. The direction of the magnetic field can be determined using the right-hand rule . This rule shows up in several places in the study of electricity and magnetism. Applied to a straight current-carrying wire, the right-hand rule says that, with your right thumb pointed in the direction of the current, the magnetic field will be in the direction in which your right fingers curl, as shown in Figure 20.13 . If the wire is very long compared to the distance r from the wire, the strength B of the magnetic field is given by

where I is the current in the wire in amperes. The SI unit for magnetic field is the tesla (T). The symbol μ 0 μ 0 —read “mu-zero”—is a constant called the “permeability of free space” and is given by

Magnetic Field Due to an Electric Current

This video describes the magnetic field created by a straight current-carrying wire. It goes over the right-hand rule to determine the direction of the magnetic field, and presents and discusses the formula for the strength of the magnetic field due to a straight current-carrying wire.

A long straight wire is placed on a table top and electric current flows through the wire from right to left. If you look at the wire end-on from the left end, does the magnetic field go clockwise or counterclockwise?

- By pointing your right-hand thumb in the direction opposite of current, the right-hand fingers will curl counterclockwise, so the magnetic field will be in the counterclockwise direction.

- By pointing your right-hand thumb in the direction opposite of current, the right-hand fingers will curl clockwise, so the magnetic field will be in the clockwise direction.

- By pointing your right-hand thumb in the direction of current, the right-hand fingers will curl counterclockwise, so the magnetic field will be in the counterclockwise direction.

- By pointing your right-hand thumb in the direction of current, the right-hand fingers will curl clockwise, so the magnetic field will be in the clockwise direction.

Now imagine winding a wire around a cylinder with the cylinder then removed. The result is a wire coil, as shown in Figure 20.14 . This is called a solenoid . To find the direction of the magnetic field produced by a solenoid, apply the right-hand rule to several points on the coil. You should be able to convince yourself that, inside the coil, the magnetic field points from left to right. In fact, another application of the right-hand rule is to curl your right-hand fingers around the coil in the direction in which the current flows. Your right thumb then points in the direction of the magnetic field inside the coil: left to right in this case.

Each loop of wire contributes to the magnetic field inside the solenoid. Because the magnetic field lines must form closed loops, the field lines close the loop outside the solenoid. The magnetic field lines are much denser inside the solenoid than outside the solenoid. The resulting magnetic field looks very much like that of a bar magnet, as shown in Figure 20.15 . The magnetic field strength deep inside a solenoid is

where N is the number of wire loops in the solenoid and ℓ ℓ is the length of the solenoid.

Electromagnets

Use this simulation to visualize the magnetic field made from a solenoid. Be sure to click on the tab that says Electromagnet. You can drive AC or DC current through the solenoid by choosing the appropriate current source. Use the field meter to measure the strength of the magnetic field and then change the number of loops in the solenoid to see how this affects the magnetic field strength.

- There will be no change in magnetic field strength when number of loops reduces from four to two.

- The magnetic field strength decreases to half of its initial value when number of loops reduces from four to two.

- The magnetic field strength increases to twice of its initial value when number of loops reduces from four to two.

- The magnetic field strength increases to four times of its initial value when number of loops reduces from four to two.

Magnetic Force

If a moving electric charge, that is electric current, produces a magnetic field that can exert a force on another magnet, then the reverse should be true by Newton’s third law. In other words, a charge moving through the magnetic field produced by another object should experience a force—and this is exactly what we find. As a concrete example, consider Figure 20.16 , which shows a charge q moving with velocity v → v → through a magnetic field B → B → between the poles of a permanent magnet. The magnitude F of the force experienced by this charge is

where θ θ is the angle between the velocity of the charge and the magnetic field. From this equation, we can see that the SI unit of magnetic field, the Tesla, is the magnetic field required to produce a 1 N force on a 1 C charge moving at 1 m/s in a direction perpendicular to the field and equivalent to the following: T = ( N ⋅ s ) ( C ⋅ m ) T = ( N ⋅ s ) ( C ⋅ m ) .

The direction of the force may be found by using another version of the right-hand rule: First, we join the tails of the velocity vector and a magnetic field vector, as shown in step 1 of Figure 20.16 . We then curl our right fingers from v → v → to B → B → , as indicated in step (2) of Figure 20.16 . The direction in which the right thumb points is the direction of the force. For the charge in Figure 20.16 , we find that the force is directed into the page.

Note that the factor sin θ sin θ in the equation F = q v B sin θ F = q v B sin θ means that zero force is applied on a charge that moves parallel to a magnetic field because θ = 0 θ = 0 and sin 0 = 0 sin 0 = 0 . The maximum force a charge can experience is when it moves perpendicular to the magnetic field, because θ = 90° θ = 90° and sin 90° = 1 . sin 90° = 1 .

Links To Physics

Magnetohydrodynamic drive.

In Tom Clancy’s Cold War novel “The Hunt for Red October,” the Soviet Union built a submarine (see Figure 20.17 ) with a magnetohydrodynamic drive that was so silent it could not be detected by surface ships. The only conceivable purpose to build such a submarine was to give the Soviet Union first-strike capability, because this submarine could sneak close to the coast of the United States and fire its ballistic missiles, destroying key military and government installations to prevent an American counterattack.

A magnetohydrodynamic drive is supposed to be silent because it has no moving parts. Instead, it uses the force experienced by charged particles that move in a magnetic field. The basic idea behind such a drive is depicted in Figure 20.18 . Salt water flows through a channel that runs from the front to the back of the submarine. A magnetic field is applied horizontally across the channel, and a voltage is applied across the electrodes on the top and bottom of the channel to force a downward electric current through the water. The charge carriers are the positive sodium ions and the negative chlorine ions of salt. Using the right-hand rule, the force on the charge carriers is found to be toward the rear of the vessel. The accelerated charges collide with water molecules and transfer their momentum, creating a jet of water that is propelled out the rear of the channel. By Newton’s third law, the vessel experiences a force of equal magnitude, but in the opposite direction.

Fortunately for all involved, it turns out that such a propulsion system is not very practical. Some back-of-the-envelope calculations show that, to power a submarine, either extraordinarily high magnetic fields or extraordinarily high electric currents would be required to obtain a reasonable thrust. In addition, prototypes of magnetohydrodynamic drives show that they are anything but silent. Electrolysis caused by running a current through salt water creates bubbles of hydrogen and oxygen, which makes this propulsion system quite noisy. The system also leaves a trail of chloride ions and metal chlorides that can easily be detected to locate the submarine. Finally, the chloride ions are extremely reactive and very quickly corrode metal parts, such as the electrode or the water channel itself. Thus, the Red October remains in the realm of fiction, but the physics involved is quite real.

- The current must flow vertically from up to down when viewed from the rear of the boat.

- The current must flow vertically from down to up when viewed from the rear of the boat.

- The current must flow horizontally from left to right when viewed from the rear of the boat.

- The current must flow horizontally from right to left when viewed from the rear of the boat.

Instead of a single charge moving through a magnetic field, consider now a steady current I moving through a straight wire. If we place this wire in a uniform magnetic field, as shown in Figure 20.19 , what is the force on the wire or, more precisely, on the electrons in the wire? An electric current involves charges that move. If the charges q move a distance ℓ ℓ in a time t , then their speed is v = ℓ / t . v = ℓ / t . Inserting this into the equation F = q v B sin θ F = q v B sin θ gives

The factor q / t in this equation is nothing more than the current in the wire. Thus, using I = q / t I = q / t , we obtain

This equation gives the force on a straight current-carrying wire of length ℓ ℓ in a magnetic field of strength B . The angle θ θ is the angle between the current vector and the magnetic field vector. Note that ℓ ℓ is the length of wire that is in the magnetic field and for which θ ≠ 0 , θ ≠ 0 , as shown in Figure 20.19 .

The direction of the force is determined in the same way as for a single charge. Curl your right fingers from the vector for I to the vector for B , and your right thumb will point in the direction of the force on the wire. For the wire shown in Figure 20.19 , the force is directed into the page.

Throughout this section, you may have noticed the symmetries between magnetic effects and electric effects. These effects all fall under the umbrella of electromagnetism , which is the study of electric and magnetic phenomena. We have seen that electric charges produce electric fields, and moving electric charges produce magnetic fields. A magnetic dipole produces a magnetic field, and, as we will see in the next section, moving magnetic dipoles produce an electric field. Thus, electricity and magnetism are two intimately related and symmetric phenomena.

Worked Example

Trajectory of electron in magnetic field.

A proton enters a region of constant magnetic field, as shown in Figure 20.20 . The magnetic field is coming out of the page. If the electron is moving at 3.0 × 10 6 m/s 3.0 × 10 6 m/s and the magnetic field strength is 2.0 T, what is the magnitude and direction of the force on the proton?

Use the equation F = q v B sin θ F = q v B sin θ to find the magnitude of the force on the proton. The angle between the magnetic field vectors and the velocity vector of the proton is 90° . 90° . The direction of the force may be found by using the right-hand rule.

The charge of the proton is q = 1.60 × 10 −19 C q = 1.60 × 10 −19 C . Entering this value and the given velocity and magnetic field strength into the equation F = q v B sin θ F = q v B sin θ gives

To find the direction of the force, first join the velocity vector end to end with the magnetic field vector, as shown in Figure 20.21 . Now place your right hand so that your fingers point in the direction of the velocity and curl them upward toward the magnetic field vector. The force is in the direction in which your thumb points. In this case, the force is downward in the plane of the paper in the z ^ z ^ -direction, as shown in Figure 20.21 .

Thus, combining the magnitude and the direction, we find that the force on the proton is ( 9.6 × 10 −13 N ) z ^ . ( 9.6 × 10 −13 N ) z ^ .

This seems like a very small force. However, the proton has a mass of 1.67 × 10 −27 kg 1.67 × 10 −27 kg , so its acceleration is a = F m = 9.6 × 10 −13 N 1.67 × 10 −27 kg = 5.7 × 10 14 m/s 2 a = F m = 9.6 × 10 −13 N 1.67 × 10 −27 kg = 5.7 × 10 14 m/s 2 , or about ten thousand billion times the acceleration due to gravity!

We found that the proton’s initial acceleration as it enters the magnetic field is downward in the plane of the page. Notice that, as the proton accelerates, its velocity remains perpendicular to the magnetic field, so the magnitude of the force does not change. In addition, because of the right-hand rule, the direction of the force remains perpendicular to the velocity. This force is nothing more than a centripetal force: It has a constant magnitude and is always perpendicular to the velocity. Thus, the magnitude of the velocity does not change, and the proton executes circular motion. The radius of this circle may be found by using the kinematics relationship.

The path of the proton in the magnetic field is shown in Figure 20.22 .

Wire with Current in Magnetic Field

Now suppose we run a wire through the uniform magnetic field from the previous example, as shown. If the wire carries a current of 1.5 A in the y ^ y ^ -direction, and the region with magnetic field is 4.0 cm long, what is the force on the wire?

Use equation F = I ℓ B sin θ F = I ℓ B sin θ to find the magnitude of the force on the wire. The length of the wire inside the magnetic field is 4.0 cm, and the angle between the current direction and the magnetic field direction is 90°. To find the direction of the force, use the right-hand rule as explained just after the equation F = I ℓ B sin θ . F = I ℓ B sin θ .

Insert the given values into equation F = I ℓ B sin θ F = I ℓ B sin θ to find the magnitude of the force

To find the direction of the force, begin by placing the current vector end to end with a vector for the magnetic field. The result is as shown in the figure in the previous Worked Example with v → v → replaced by I → I → . Curl your right-hand fingers from I → I → to B → B → and your right thumb points down the page, again as shown in the figure in the previous Worked Example. Thus, the direction of the force is in the x ^ x ^ -direction. The complete force is thus ( 0.12 N ) x ^ ( 0.12 N ) x ^ .

The direction of the force is the same as the initial direction of the force was in the previous example for a proton. However, because the current in a wire is confined to a wire, the direction in which the charges move does not change. Instead, the entire wire accelerates in the x ^ x ^ -direction. The force on a current-carrying wire in a magnetic field is the basis of all electrical motors, as we will see in the upcoming sections.

Practice Problems

What is the magnitude of the force on an electron moving at 1.0 × 10 6 m/s perpendicular to a 1.0-T magnetic field?

- 0.8 × 10 –13 N

- 1.6 × 10 –14 N

- 0.8 × 10 –14 N

- 1.6 × 10 –13 N

A straight 10 cm wire carries 0.40 A and is oriented perpendicular to a magnetic field. If the force on the wire is 0.022 N, what is the magnitude of the magnetic field?

- 1.10 × 10 –2 T

- 0.55 × 10 –2 T

Check Your Understanding

- Either the south pole of magnet 1 is closer to the north pole of magnet 2 or the north pole of magnet 1 is closer to the south pole of magnet 2.

- Either the south poles of both the magnet 1 and magnet 2 are closer to each other or the north poles of both the magnet 1 and magnet 2 are closer to each other.

- Not enough information is given to draw any conclusion about the orientation of the magnets.

Describe methods to demagnetize a ferromagnet.

- by cooling, heating, or submerging in water

- by heating, hammering, and spinning it in external magnetic field

- by hammering, heating, and rubbing with cloth

- by cooling, submerging in water, or rubbing with cloth

- The directional lines present inside and outside the magnetic material that indicate the magnitude and direction of the magnetic force.

- The directional lines present inside and outside the magnetic material that indicate the magnitude of the magnetic force.

- The directional lines present inside the magnetic material that indicate the magnitude and the direction of the magnetic force.

- The directional lines present outside the magnetic material that indicate the magnitude and the direction of the magnetic force.

As an Amazon Associate we earn from qualifying purchases.

This book may not be used in the training of large language models or otherwise be ingested into large language models or generative AI offerings without OpenStax's permission.

Want to cite, share, or modify this book? This book uses the Creative Commons Attribution License and you must attribute Texas Education Agency (TEA). The original material is available at: https://www.texasgateway.org/book/tea-physics . Changes were made to the original material, including updates to art, structure, and other content updates.

Access for free at https://openstax.org/books/physics/pages/1-introduction

- Authors: Paul Peter Urone, Roger Hinrichs

- Publisher/website: OpenStax

- Book title: Physics

- Publication date: Mar 26, 2020

- Location: Houston, Texas

- Book URL: https://openstax.org/books/physics/pages/1-introduction

- Section URL: https://openstax.org/books/physics/pages/20-1-magnetic-fields-field-lines-and-force

© Jan 19, 2024 Texas Education Agency (TEA). The OpenStax name, OpenStax logo, OpenStax book covers, OpenStax CNX name, and OpenStax CNX logo are not subject to the Creative Commons license and may not be reproduced without the prior and express written consent of Rice University.

What is Magnetization?

Experiment: Ask your mom or dad (or your teacher) for some metal paper-clips and a magnet. Can you pick up paper clips with the magnet? Can you pick up the paper clips with other paper clips?

Now, rub a paper clip with the magnet. Can you pick up other paper clips with it now?

ScienceSphere.blog

Magnetic Conversations: What Did The Paper Clip Say To The Magnet?

In this blog post, we will explore the concept of magnetic conversations through the perspective of two characters: the paper clip and the magnet. These inanimate objects may seem ordinary, but they have a lot to teach us about the power of communication and connection.

Table of Contents

Brief Explanation of Magnetic Conversations

Magnetic conversations refer to those interactions that draw people together, creating a strong bond and leaving a lasting impact. Just like how a magnet attracts a paper clip, these conversations have the ability to captivate our attention and create a sense of connection.

Introducing the Paper Clip and the Magnet

To better understand the concept of magnetic conversations, let’s introduce our characters: the paper clip and the magnet. The paper clip, a simple and unassuming object, represents our curiosity and desire to engage in conversation. On the other hand, the magnet symbolizes the captivating qualities that draw us towards certain individuals or topics.

As we delve into the perspectives of these characters, we will uncover valuable insights about the art of conversation and the importance of open-mindedness.

Stay tuned for the next section where we explore the paper clip’s perspective and its role in the magnetic conversation.

The Paper Clip’s Perspective

The paper clip, a simple yet versatile tool, plays a crucial role in our daily lives. It holds together important documents, keeps our papers organized, and serves as a symbol of efficiency. However, beyond its practical uses, the paper clip also has a unique perspective on the world around it.

Exploring the paper clip’s role and purpose

From the paper clip’s point of view, its purpose extends beyond its physical function. It sees itself as a connector, bringing together different pieces of information and ideas. It takes pride in its ability to keep things in order and create a sense of structure.

Discussing the paper clip’s curiosity about the magnet

Curiosity is a fundamental trait of the paper clip. It wonders about the magnet, a mysterious and powerful force that it often encounters. The paper clip is intrigued by the magnet’s ability to attract and repel objects, and it yearns to understand the science behind this phenomenon.

Highlighting the paper clip’s desire to engage in conversation

Despite being an inanimate object, the paper clip longs for connection and interaction. It desires to engage in conversations, not only with other paper clips but also with different objects it encounters. It believes that through conversation, it can gain new perspectives and expand its understanding of the world.

The paper clip’s perspective reminds us of the importance of curiosity and the desire to learn. It teaches us that even the simplest objects can have a unique outlook on life. By embracing curiosity, we can open ourselves up to new experiences and opportunities for growth.

In the next section, we will explore the magnet’s perspective and understand how these two characters come together in a magnetic conversation. Stay tuned for an intriguing insight into the magnet’s world.

The Magnet’s Perspective

The magnet, a powerful and enigmatic character in the conversation, holds a unique perspective on the interaction with the paper clip. Understanding the magnet’s characteristics and abilities is crucial to comprehending its attraction to the paper clip and its response to the paper clip’s curiosity.

Understanding the magnet’s characteristics and abilities

The magnet possesses an inherent magnetic field that exerts a force on objects within its range. This force, known as magnetism, is what draws the magnet to certain materials, including the paper clip. The magnet’s ability to attract and repel objects is a fundamental aspect of its nature.

The magnet’s magnetic field is created by the alignment of its atoms, which have tiny magnetic fields of their own. When these atoms align in the same direction, they create a stronger magnetic field. This alignment is achieved through a process called magnetization, which involves exposing the magnet to a strong external magnetic field or by rubbing it against another magnet.

Explaining the magnet’s attraction to the paper clip

The magnet’s attraction to the paper clip stems from the paper clip’s ferromagnetic properties. Ferromagnetic materials, such as iron or steel, contain atoms that can easily align with an external magnetic field. When the magnet comes into proximity with the paper clip, its magnetic field induces a magnetic response in the paper clip’s atoms, causing them to align with the magnet’s field.

This alignment creates a magnetic connection between the magnet and the paper clip, resulting in the paper clip being drawn towards the magnet. The strength of this attraction depends on various factors, including the distance between the magnet and the paper clip, the strength of the magnet’s magnetic field, and the magnetic properties of the paper clip.

Describing the magnet’s response to the paper clip’s curiosity

When the paper clip exhibits curiosity about the magnet, the magnet responds with a sense of intrigue and fascination. The magnet recognizes the paper clip’s willingness to engage in conversation and explore the mysteries of magnetism. It understands that the paper clip’s curiosity is a reflection of its own magnetic nature.

The magnet, being a silent observer, appreciates the opportunity to share its knowledge and experiences with the paper clip. It responds by revealing the wonders of magnetism, explaining the science behind its attraction and repulsion, and shedding light on the magnetic field it generates. The magnet’s response is filled with a sense of pride and satisfaction, knowing that it can contribute to the paper clip’s understanding of the world.

In this exchange, the magnet and the paper clip form a unique bond, a magnetic connection that transcends their physical properties. The magnet’s response to the paper clip’s curiosity deepens their connection, fostering a sense of mutual respect and admiration.

Understanding the magnet’s perspective is essential to grasp the intricacies of the conversation between the paper clip and the magnet. It allows us to appreciate the magnet’s role as a teacher and guide, imparting knowledge and wisdom to the curious paper clip. By delving into the magnet’s characteristics, attraction, and response, we gain a deeper understanding of the magnetic connection that binds these two characters together.

The Conversation Unfolds

In this section, we will delve into the dialogue between the paper clip and the magnet, showcasing the different perspectives and insights shared, and highlighting the magnetic connection between the two characters.

Presenting the dialogue between the paper clip and the magnet

The conversation between the paper clip and the magnet begins with the paper clip expressing its curiosity about the magnet. It asks the magnet, “What makes you so attractive? Why do I feel drawn to you?” The magnet, with a gentle hum, responds, “It’s my magnetic field. It’s a force that pulls objects like you towards me.”

The paper clip, intrigued by the magnet’s response, further inquires, “But why do you have this magnetic field? What purpose does it serve?” The magnet explains, “My magnetic field is a result of the alignment of my atoms. It allows me to attract certain materials, like iron or steel.”

Showcasing the different perspectives and insights shared

As the conversation progresses, the paper clip shares its perspective on its role and purpose. It reveals that its primary function is to hold papers together, keeping them organized and preventing them from getting lost. The magnet, listening attentively, acknowledges the importance of the paper clip’s role and appreciates its ability to bring order to chaotic situations.

The magnet then shares its own perspective, explaining that its purpose extends beyond attracting objects. It reveals that magnets are used in various applications, such as generating electricity, powering motors, and even in medical devices like MRI machines. The paper clip, amazed by the magnet’s versatility, realizes that there is much more to magnets than meets the eye.

Highlighting the magnetic connection between the two characters

Throughout the conversation, a magnetic connection between the paper clip and the magnet becomes evident. The paper clip, initially drawn to the magnet’s magnetic field, starts to understand that their connection goes beyond mere attraction. They both share a desire to engage in conversation, to learn from each other, and to explore the possibilities that arise from their interaction.

As the conversation unfolds, the paper clip and the magnet discover that their unique qualities and abilities complement each other. The paper clip’s organizational skills and the magnet’s magnetic field create a harmonious partnership, symbolizing the power of collaboration and synergy.

In this section, we witnessed the conversation between the paper clip and the magnet, where they shared their perspectives, insights, and formed a magnetic connection. This dialogue highlights the importance of communication and connection in our own lives.

By engaging in meaningful conversations, we can learn from others, gain new perspectives, and foster deeper connections. Just like the paper clip and the magnet, we can discover that our unique qualities and abilities can complement those of others, leading to powerful collaborations and positive outcomes.

So, let us embrace the concept of magnetic conversations, where curiosity, open-mindedness, and a willingness to engage can lead to transformative experiences. Let us seek out conversations that attract us, just like the paper clip was drawn to the magnet, and let us create connections that have the power to change our lives for the better.

Lessons Learned

In this section, we will delve into the significance of the conversation between the paper clip and the magnet and explore the valuable lessons we can learn from their interaction.

The Power of Communication and Connection

The conversation between the paper clip and the magnet highlights the importance of effective communication and meaningful connections. Communication is not just about exchanging words; it is about truly understanding and connecting with others. The paper clip’s curiosity and the magnet’s response demonstrate the power of engaging in conversations that go beyond surface-level interactions.

When we engage in meaningful conversations , we open ourselves up to new perspectives, ideas, and insights. These conversations allow us to broaden our horizons and gain a deeper understanding of the world around us. By actively listening and engaging in dialogue, we can foster stronger connections with others and build more meaningful relationships.

The Role of Open-Mindedness and Curiosity

The paper clip’s curiosity about the magnet serves as a reminder of the importance of open-mindedness . By being open to new experiences and ideas, we can expand our knowledge and challenge our preconceived notions. The paper clip’s willingness to engage in conversation with the magnet, despite their differences, demonstrates the power of embracing diversity and seeking out different perspectives.

Curiosity is a catalyst for growth and learning. It fuels our desire to explore, question, and seek answers. The paper clip’s curiosity about the magnet not only leads to a fascinating conversation but also encourages us to embrace our own curiosity. By asking questions and seeking knowledge, we can continuously learn and grow.

Embracing Differences and Finding Common Ground

The conversation between the paper clip and the magnet showcases the beauty of embracing differences and finding common ground. Despite their contrasting characteristics, the paper clip and the magnet are able to connect and engage in a meaningful conversation.

In our own lives, we encounter people with different backgrounds, beliefs, and perspectives. Instead of focusing on our differences, we can strive to find common ground and build bridges of understanding. By recognizing and appreciating the unique qualities and strengths of others, we can foster a sense of unity and create a more inclusive and harmonious world.

The conversation between the paper clip and the magnet serves as a metaphor for the power of magnetic conversations in our own lives. Through effective communication, open-mindedness, and embracing differences, we can create meaningful connections and gain valuable insights.

As we reflect on the lessons learned from the paper clip and the magnet, let us remember the importance of engaging in conversations that go beyond the surface. Let us embrace curiosity, open-mindedness, and a willingness to connect with others. By doing so, we can foster deeper relationships, broaden our perspectives, and create a more interconnected world. So, let’s start having more magnetic conversations and see the transformative impact they can have on our lives.

Decoding Racial Triangulation: Unveiling Its Impact On English Language

Decoding The P Vs. Q Inventory Systems: Unveiling The Key Differences

Unveiling The Mystery: What Is Milk Whitener And How Does It Work?

Decoding The Mystery: What Exactly Is A Dna Size Standard?

Unveiling The Secrets: What Is Hearth Bread And Why It’s A Must-Try

Decoding The Mystery: What Time Is 22 32 In English Language?

Decoding Labor Demand: Unveiling The Elasticity Mystery

Demystifying Abrams Law: Understanding Its Impact In English Language

Curiosity Bites: What Happens If You Eat Concrete?

Decoding The Sexual Slang: What Does “Hh” Mean?

Leave a Comment Cancel reply

Save my name, email, and website in this browser for the next time I comment.

Item added to your cart

Everything you need to know about using inkjet printable magnetic paper.

Everything You Need to Know About Using Inkjet Magnetic Paper

Inkjet magnetic paper has become increasingly popular in recent years as a versatile and creative option for printing various materials. Whether you're looking to make personalized magnets for your fridge or design eye-catching marketing materials, inkjet magnetic paper offers endless possibilities. In this article, we will explore everything you need to know about using inkjet magnetic paper and how to unleash your creativity.

What is Inkjet Magnetic Paper?

Inkjet magnetic paper is a specially designed material that combines the convenience of printable paper with the magnetic properties of magnets. It allows you to print your designs, artwork, or text using an inkjet printer and then turn them into magnets or other magnetic materials. The printable side of the paper is coated to receive ink from an inkjet printer, while the other side features a magnetic backing that allows the paper to adhere to metal surfaces.

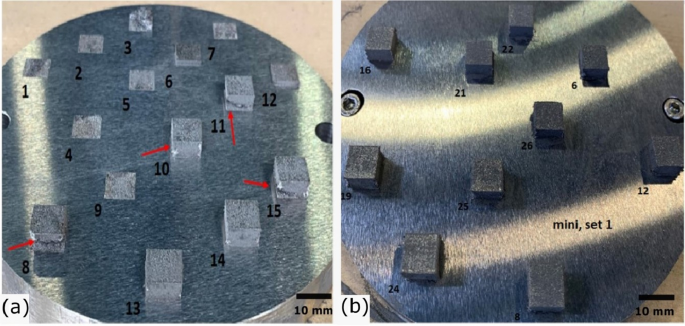

How Does Inkjet Magnetic Paper Work?

Using inkjet magnetic paper is straightforward. Once you have your design ready, you can load the inkjet magnetic paper into your inkjet printer, making sure to insert it correctly based on the printer's guidelines. It's essential to choose the appropriate print settings for the best results. Generally, selecting the photo or high-quality printing option will provide vibrant colors and sharp details.

After printing, allow the ink to dry completely before handling the paper. Once dry, you can cut out the printed designs using scissors, a craft knife, or a paper cutter, depending on your preference and the complexity of the shapes. Peel off the protective backing to reveal the adhesive magnetic side, and your printed designs are ready to stick to any magnetic surface.

What Can You Create with Inkjet Magnetic Paper?

The possibilities for using inkjet magnetic paper are practically limitless. Here are some exciting ideas to inspire your creativity:

Custom Magnets: Personalize your fridge or magnetic board by printing photos, quotes, or artwork onto inkjet magnetic paper. It's a fantastic way to showcase your favorite memories or add a touch of uniqueness to your space.

Promotional Materials: Create eye-catching promotional magnets for your business. Print your logo, contact information, or special offers on inkjet magnetic paper and distribute them to potential customers. They can serve as memorable and useful reminders of your brand.

Educational Tools: Design educational magnets for children by printing letters, numbers, shapes, or interactive learning materials. These magnets can make learning fun and engaging for kids.

Party Favors and Gifts: Craft personalized party favors or unique gifts using inkjet magnetic paper. Print custom designs or messages to create memorable keepsakes for birthdays, weddings, or other special occasions.

Organizational Tools: Print labels or signs on inkjet magnetic paper to help you stay organized. Use them on metal storage bins, filing cabinets, or whiteboards for easy repositioning.

Tips for Using Inkjet Magnetic Paper:

To ensure the best results when using inkjet magnetic paper, consider the following tips:

Choose the Right Printer: Inkjet magnetic paper works well with most inkjet printers, but it's essential to check your printer's specifications to ensure compatibility.

Test Print: Before printing your final designs, consider doing a test print on regular paper to verify colors, layout, and alignment. This way, you can make any necessary adjustments before using the inkjet magnetic paper.

Handle with Care: Inkjet magnetic paper is relatively thin and can be delicate. Handle it carefully to avoid tearing or creasing the paper, which could affect the final results.

Store Properly: Keep your inkjet magnetic paper in a cool, dry place, away from direct sunlight or moisture, to maintain its quality and adhesive properties.

Experiment and Have Fun: Inkjet magnetic paper offers a great opportunity to experiment with different designs, colors, and shapes. Let your creativity run wild and have fun exploring all the possibilities.

Inkjet magnetic paper is a fantastic tool for adding a personal touch to your surroundings, promoting your business, or creating unique gifts. With a little imagination and the right printing techniques, you can turn ordinary prints into extraordinary magnets. So grab some inkjet magnetic paper and let your creativity soar!

- Choosing a selection results in a full page refresh.

- Opens in a new window.

- The Woodlands

Just in time for this year's Charles Schwab Challenge, Fort Worth's Colonial Golf Course has undergone a makeover.

A fabled red plaid jacket awaits the winner of the 2024 Charles Schwab Challenge. (Photo by Erich Schlegel-USA TODAY Sports)

2023 winner Emiliano Grillo sips champagne seated next to the Leonard Trophy.

The Wall of Champions tells the storied history of the longest-running PGA Tournament.

Fort Worth’s Colonial Golf Course Gets A Major Facelift Before The Annual Charles Schwab Challenge

New state-of-the-art improvements, same time-honored traditions.

A lot has changed at Fort Worth’s Colonial Country Club since it hosted the 2023 Charles Schwab Challenge. The storied course that Marvin Leonard opened in 1936, and then introduced in legendary fashion as it hosted the 1941 U.S. Open, has achieved a major make-over ― modernizing and renovating the oak-lined fairways to great effect.

Renowned golf course architects Gil Hanse (who also unveiled PGA Frisco in 2022) and Jim Wagner embarked on the most significant renovation project in the course’s storied history. This year’s tournament will serve as its big reveal.

The project addressed every aspect of the course infrastructure, including a state-of-the-art irrigation system as well as new bunkers, tees, and greens ― so while PGA Tour pros who have played Colonial many times, return to Fort Worth this May, it won’t be the same course they remember.

“It will still be the revered Colonial course we are all familiar with seeing and playing, but the Hanse work will improve, update, and maximize this legendary course and routing,” says Colonial Country Club GM Frank Cordeiro of the major overhaul.

Historic Re-Envisioning

State-of-the-art improvements like new subterranean cooling and heating systems for the green complexes will manage and adjust soil temperatures for superior growth and plant health ― maintaining the legendary landscape throughout North Texas’ notoriously wild weather swings.

The biggest changes to the course were on par three holes No. 8 and No. 13, which were drastically changed by the 1969 flood-control project, which was undertaken by the Corps of Engineers ― dramatically altering the Trinity River channel, and forming the north border of the golf course .

Discover the Sweetness of Peche: Shop Le Creuset's Newest Color at Bering's!

“The par three eighth hole was shifted left into more of a north-to-south orientation, in somewhat of a mirror image of the original hole, with a creek on the left side rather than a river on the right,” according to a release. “The 13th green also moved back and left, with bunkers added in front of the hole.”